What Is a Sump Pump? Different Types and How it Works

Feb 10, 2026

A sump pump is an essential piece of equipment that removes accumulated water from areas prone to flooding. Although they are most often placed in residential basements, sump pumps can also be found in construction sites, underground facilities, and anywhere else you need to control groundwater.

Sump pumping systems serve as dewatering solutions that safeguard building foundations, equipment and workers from flooding and seepage and permanent water damage in building contracting services and marine operations.

What Is a Sump Pump?

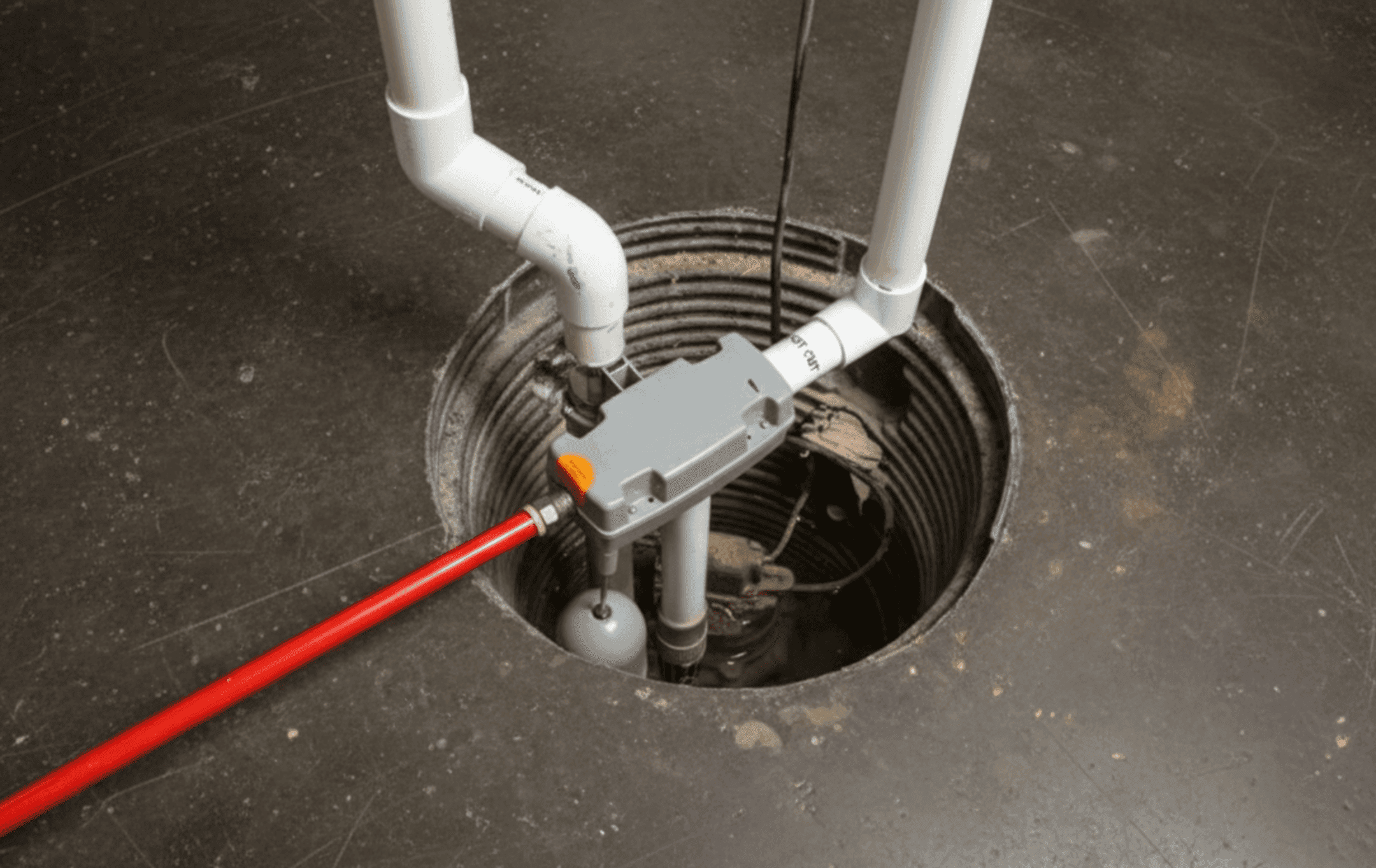

A sump pump is a mechanical pump used to remove water that has accumulated in a water-collecting sump basin, commonly found in the basements of homes. It is designed to receive and divert excess water from floors away from areas at risk through a connected pipe or drain.

Industrial settings such as in marine facilities, construction sites, and even in mining areas, use sump pumps to control groundwater that enters basements, tunnels, shipyards and offshore facilities. Coastal regions and reclaimed land areas require these systems because high water tables prevent effective passive drainage systems from working properly.

How Sump Pumps Work

The sump pumps operate through their automatic system, which controls water level detection to begin their discharge process. The sump pit fills with water when groundwater and rainwater enter the pit or when process-related leaks from the coal-ash slurry wall occur.

Sump pump motors activate when water reaches predetermined float switch or electronic sensor detection points. The pump uses its internal impeller system to move water through its discharge pipe, which leads to designated drainage areas that operate away from your property. The pump automatically shuts down when water levels drop, allowing you to operate it without monitoring.

Many sewage treatment facilities utilize submersible designs, including portable type and all cast-iron automatic pumps, which can be submersed under the liquid and are used for temporary or emergency bypass pumping.

Types of Sump Pumps

Submersible Sump Pumps

Submersible sump pumps are installed directly inside the sump pit and operate fully underwater. The pumps use a sealed design, which enables them to manage industrial wastewater and marine water that contains solid particles in higher flow volumes. These pumps are widely used in construction excavations, offshore platforms, and underground facilities where continuous exposure to water is expected.

Pedestal Sump Pumps

Pedestal sump pumps are positioned above the sump pit, with only the intake pipe submerged. The system requires less maintenance because its motor remains visible, but it operates better in situations that need specialized equipment. Industrial projects use pedestal pumps as their primary choice for secondary and backup pumping systems.

Sewage Sump Pumps

Sewage sump pumps are built to process wastewater that contains solid waste and other materials. The pumps use industrial-grade impellers, which work with strengthened pump bodies to stop blockages from occurring. The equipment is designed for use in shipyards, offshore facilities, and industrial plants that need to move wastewater from underground storage systems.

Battery Backup Sump Pumps

Battery backup sump pumps provide emergency operation during power failures. In marine and offshore installations, these systems are often combined with diesel generators or uninterruptible power supplies to ensure continuous dewatering during storms or electrical outages.

Sump Pump Installation in Industrial Environments

Sump pump installation begins with constructing a sump pit at the lowest elevation point of the site. The pit is lined with reinforced concrete or polymer chambers designed to withstand soil pressure and water flow.

The pump system at the site requires installation within the pit area, together with connecting the discharge pipeline, which has a non-return valve installed to stop backflow. The installation process of engineered systems needs to include electrical control panels with water level sensors, backup power systems, and remote monitoring alarm systems.

Sump pumps in large-scale projects form part of a full sump pumping dewatering system that includes multiple pits, staged pumping zones, and automated flow control to manage fluctuating groundwater levels.

Difference Between Sump Pump and Submersible Pump

Although the terms are often used interchangeably, sump pumps and submersible pumps are not the same. The key difference lies in their purpose and design, even though many modern sump pumps use submersible technology.

Feature | Sump Pump | Submersible Pump |

Definition | A pump designed specifically to remove water from a sump pit. | A pump designed to operate fully submerged in liquid. |

Primary Purpose | Groundwater and flood control. | General fluid transfer and pumping. |

Installation | Installed inside a sump pit or chamber. | Installed directly inside the liquid being pumped. |

Typical Applications | Basements, construction dewatering, foundations. | Wastewater, bilge systems, industrial fluids. |

Design Type | Can be submersible or pedestal. | Always fully submersible. |

Industry Use | Building contracting and dewatering systems. | Marine, oil and gas, wastewater, and industrial processes. |

Choosing the Right Sump Pump Capacity

Pump capacity is determined by flow rate and motor power. Smaller installations may operate with fractional horsepower units, while industrial dewatering systems typically use higher-capacity models.

The 1.5 HP sump pump functions as a standard pump that construction sites, marine yards and infrastructure projects use to handle substantial water flow requirements. The pumps deliver enhanced performance through their ability to discharge higher volumes of water while operating continuously under demanding conditions.

Capacity selection is a function of the volume of groundwater, the size of the pit, the distance to discharge, and operating conditions. Improperly sizing a pump can result in inefficiency, premature failure of the pumping unit, or system blockage.

Different Uses of Sump Pumps in Industry

Sump pumps are essential across industrial environments where water control is critical for safety, equipment protection, and operational efficiency. They support both temporary and permanent dewatering needs in demanding conditions.

Oil and gas facilities: Used to manage accumulated water in processing areas, equipment zones, and offshore platforms, helping prevent corrosion, electrical hazards, and system downtime.

Marine and shipyard operations: Applied in bilge water removal, dry dock drainage, and runoff control to keep vessels, work areas, and mechanical systems dry and operational.

Building contracting services: Installed during basement construction, tunneling, and foundation works to continuously remove groundwater and maintain stable, dry work environments.

Port and coastal infrastructure: Used in docks, harbors, and coastal facilities where tidal movement and stormwater create unpredictable water ingress.

Sump pumping dewatering systems: Deployed in large-scale projects to maintain soil stability, reduce hydrostatic pressure, and protect structural integrity throughout construction and operation phases.

Sump Pumps in Industrial Infrastructure

The current sump pumping systems use digital monitoring systems to track water levels and pump operations, energy consumption and maintenance schedules. The system enables engineers to predict equipment failures while they optimize system efficiency and decrease operating time.

In industrial engineering environments such as those supported by Automech Group, sump pumps are no longer standalone devices but part of comprehensive dewatering and infrastructure systems that combine mechanical engineering, automation, and environmental control.